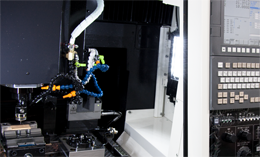

Mold Making Technology

Our Mold Making Division has sufficient plant equipment to create high-precision products even without skilled workers based on the theme of creating low-priced molds with short lead times leveraging advanced machines and technology.

Our Mold Making Division has sufficient plant equipment to create high-precision products even without skilled workers based on the theme of creating low-priced molds with short lead times leveraging advanced machines and technology.

Moreover, our proprietary system offers the accuracy of 1/1,000mm. By directly transferring electric discharge machining data from CAD/CAM and automating the process, we are able to offer shorter delivery times.

We have the latest air conditioning equipment, which is important for mold making, and we provide high-precision molds in an environment with a temperature difference of +/-0.5.

Mold Making Equipment

| High-precision, high-speed, small-diameter micro-fabrication machine | Roku-Roku

-Android x 1 |

|---|---|

| High-precision, high-speed, small-diameter micro-fabrication machine | Roku-Roku -MEGA-SS600 x 1 |

| Small high-precision engraving electric discharge machine | Mitsubishi Electric

-EA8PV-ADVANCE x 1 |

| High-precision wire electrical discharge machine | Mitsubishi Electric

-MP1200 x 1 |

| Fine hole electric discharge machine | Mitsubishi Electric

-MEMH43S x 1 |

| Precision profile grinder | Okamoto Machinery

-PFG500A II x 1 |

| Profile grinder | Kuroda Precision Industries

1 |

| General-purpose jig milling machine | Makino

1 |

| Profile projector | Nikon

1 |

| Tool microscope | Nikon/Olympus

21 |

| 3D measuring machine | Mitsutoyo

CRYSTA-APEX S544 x 1 |

| 3D CAD/CAM | 2 |

| 3D CAM | 1 |